Get Welder Performance Qualification Record Form

Key takeaways

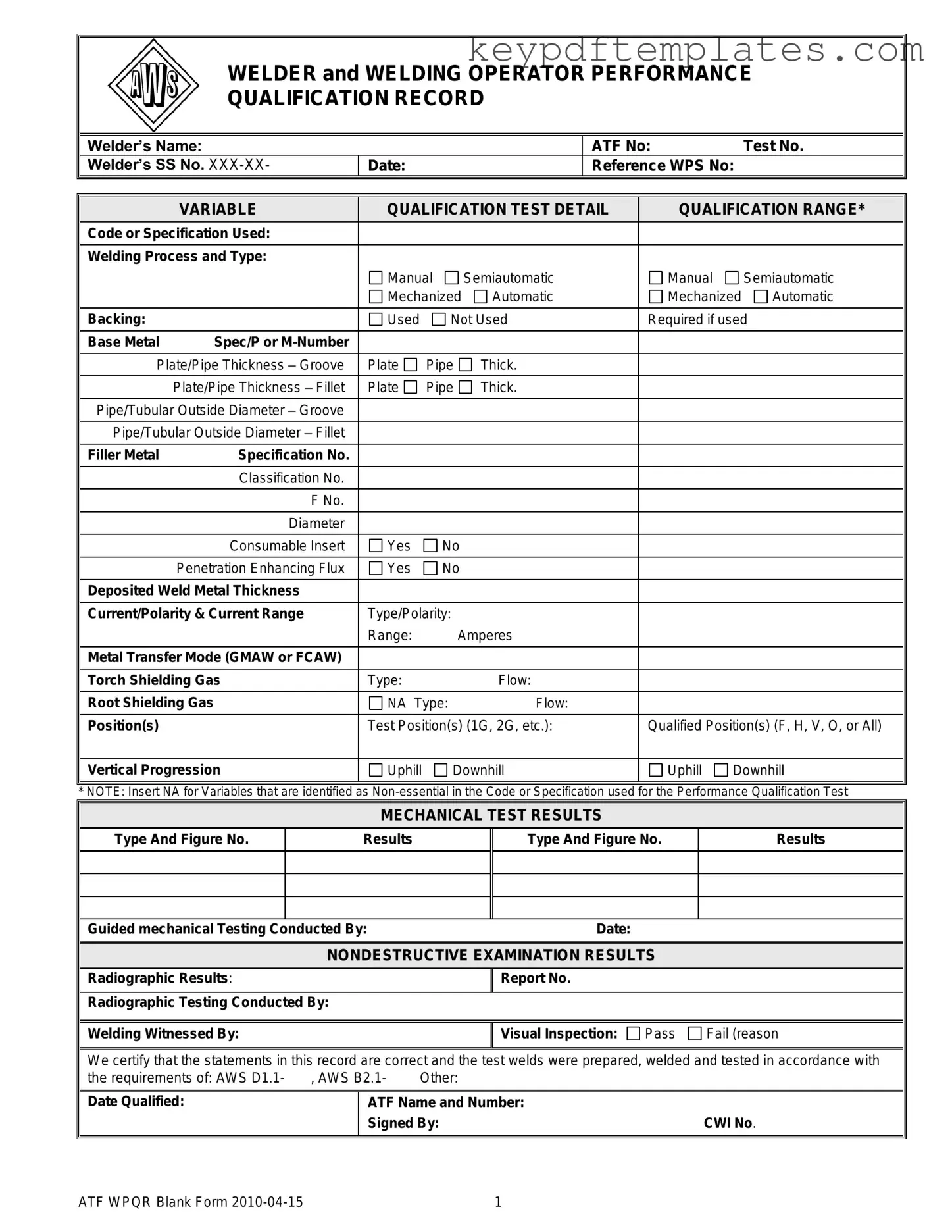

Filling out the Welder Performance Qualification Record form is crucial for ensuring that welders meet industry standards. Here are key takeaways to consider:

- Accurate Information: Ensure that all personal details, including the welder's name and identification numbers, are filled out correctly.

- Reference WPS: Include the Welding Procedure Specification (WPS) number to link the qualification to specific procedures.

- Qualification Range: Clearly indicate the qualification range for variables such as base metal thickness and welding positions.

- Mechanical Testing: Document the results of any mechanical tests conducted. This information is vital for validating the welder's skills.

- Non-Destructive Examination: Record the results of any non-destructive testing, such as radiographic tests. This adds credibility to the qualification.

- Certification: Acknowledge that all statements made in the record are accurate. This certification is essential for compliance.

- Signatures: Ensure that the form is signed by the appropriate personnel, including the Certified Welding Inspector (CWI), to validate the qualification.

Completing this form correctly is not just a formality; it is a critical step in maintaining safety and quality in welding practices. Act promptly to ensure all details are accurate and compliant.

Similar forms

- Welding Procedure Specification (WPS): Similar to the Welder Performance Qualification Record, the WPS outlines the specific procedures and parameters for welding. It details the materials, techniques, and equipment to be used, ensuring consistency and safety in the welding process.

- Procedure Qualification Record (PQR): This document verifies that a welding procedure can produce a weld that meets the required standards. It includes details about the welding parameters and the results of tests performed on the welds, similar to the performance qualifications noted in the Welder Performance Qualification Record.

- Certificate of Compliance: This document certifies that a product or service meets specified standards. Like the Welder Performance Qualification Record, it provides assurance of quality and adherence to regulations.

- Inspection Report: An inspection report documents the findings of a quality inspection. It parallels the Welder Performance Qualification Record by confirming that the welding meets the necessary standards through visual and other non-destructive examinations.

- Material Test Report (MTR): This report provides details about the materials used in the welding process. It is similar to the Welder Performance Qualification Record in that it ensures the materials meet specified requirements for safety and performance.

- Welder Certification: This document certifies that a welder has the necessary skills and knowledge to perform welding tasks. It is akin to the Welder Performance Qualification Record, which verifies the welder's capabilities based on specific tests.

- Non-Destructive Testing (NDT) Report: An NDT report records the results of tests that evaluate the integrity of welds without causing damage. This is similar to the non-destructive examination results section of the Welder Performance Qualification Record.

- Quality Control Plan: This plan outlines the procedures and standards for maintaining quality during the welding process. It shares similarities with the Welder Performance Qualification Record by emphasizing the importance of adherence to quality standards.

- Vehicle Purchase Agreement: This form is essential for the sale and purchase of vehicles in California. It includes vital information like the sale price and vehicle details, ensuring clarity in the transaction. You can print the document for your records.

- Welding Inspection Checklist: This checklist is used to ensure that all aspects of the welding process meet specified criteria. It is similar to the Welder Performance Qualification Record in that it helps verify compliance with established standards.

- Welding Log: A welding log tracks the details of each welding operation, including parameters and conditions. It is akin to the Welder Performance Qualification Record as it documents the performance of welders and the specifics of each weld.

Misconceptions

Understanding the Welder Performance Qualification Record (WPQR) is essential for both welders and employers. However, several misconceptions exist about this important document. Here are nine common misconceptions:

- Only certified welders need a WPQR. In reality, anyone performing welding tasks can benefit from having a WPQR, as it provides a record of their skills and qualifications.

- The WPQR is the same as a welding certification. While they are related, the WPQR is a record of the qualifications achieved during testing, whereas a welding certification is an official recognition of those qualifications.

- Once a WPQR is issued, it never needs updating. This is incorrect. If a welder changes processes, materials, or positions, a new WPQR may be required to reflect those changes.

- The WPQR only covers one type of welding. A WPQR can encompass multiple welding processes, provided the welder has qualified for each one.

- Visual inspection is the only requirement for qualification. This is a misconception. A WPQR typically includes both destructive and non-destructive testing results to ensure thorough evaluation.

- The WPQR is only necessary for large projects. Smaller projects also benefit from having a WPQR, as it demonstrates the welder's capabilities and adherence to standards.

- All WPQRs are the same. Each WPQR is unique to the welder and the specific qualifications achieved, reflecting different processes, materials, and tests.

- Anyone can fill out a WPQR. Only qualified personnel, such as certified welding inspectors, should complete the WPQR to ensure accuracy and compliance.

- Having a WPQR guarantees employment. While a WPQR is a valuable asset, it does not guarantee a job. Employers consider various factors when hiring, including experience and fit for the role.

Addressing these misconceptions can help welders and employers better understand the importance of the WPQR in the welding industry.

More PDF Templates

Texas Drivers License Renewal Form Dl-43 - DL-43 provides a streamlined process for correcting registration information.

The Florida Articles of Incorporation form is a crucial legal document that serves to establish a corporation in the state of Florida. It details important information regarding the corporation, such as its name, purpose, and structure. To learn more about this essential step in forming a business entity in Florida, visit allfloridaforms.com/.

Share Transfer Form - Capture the stockholder's place of residence for official records.

Form Specs

| Fact Name | Details |

|---|---|

| Purpose | The Welder Performance Qualification Record form verifies a welder's skills and qualifications for specific welding processes. |

| Welder Information | It includes essential details such as the welder's name, social security number, and test number. |

| Welding Process | The form specifies the type of welding process used, including manual, semiautomatic, mechanized, and automatic methods. |

| Qualification Range | It outlines the qualification range for various parameters, including base metal specifications and thicknesses. |

| Mechanical Testing | Results from mechanical tests conducted on the welds are documented, ensuring compliance with industry standards. |

| Non-Destructive Examination | The form records results from non-destructive tests, such as radiographic and visual inspections, to assess weld integrity. |

| Governing Laws | In some states, specific laws govern the use of this form, such as AWS D1.1 and AWS B2.1 standards. |

| Certification | The form includes a certification statement confirming the accuracy of the information and adherence to testing requirements. |

| Signature Requirement | A qualified individual, such as a Certified Welding Inspector (CWI), must sign the form to validate the results. |

Documents used along the form

The Welder Performance Qualification Record (WPQR) is a critical document in the welding industry, serving as evidence of a welder's ability to perform welding tasks according to specific standards. Several other forms and documents complement the WPQR, each playing a unique role in the qualification process. Below is a list of these documents, along with brief descriptions of their purposes.

- Welding Procedure Specification (WPS): This document outlines the specific welding parameters and procedures to be followed during welding. It includes details on materials, welding processes, and techniques to ensure consistent and quality welds.

- Welder Certification Card: Issued to welders who have successfully completed a qualification test. This card serves as proof of a welder's certified skills and may be required by employers or regulatory bodies.

- Test Report: This document contains the results of the performance qualification tests, including mechanical and non-destructive testing outcomes. It provides essential data for assessing a welder's capabilities.

- Inspection Report: Generated by an inspector, this report details the findings of visual inspections or other assessments of the welds. It confirms whether the welds meet the required standards.

- Non-Destructive Testing (NDT) Report: This report documents the results of non-destructive testing methods, such as radiography or ultrasonic testing, used to evaluate the integrity of welds without damaging them.

- Material Certification: This document verifies the properties and specifications of the materials used in welding. It ensures that the materials comply with the required standards for the project.

- Welder Training Records: These records provide evidence of a welder's training history, including courses completed and skills acquired. They may be necessary for certain certifications or employment opportunities.

- Quality Control Plan: This document outlines the procedures and standards for quality assurance in welding operations. It includes guidelines for inspections, testing, and corrective actions to maintain quality.

- Trailer Bill of Sale Form: For transferring ownership of trailers, utilize the important Trailer Bill of Sale form elements to ensure all details are accurately documented.

- Safety Data Sheets (SDS): These sheets provide information on the safe handling and potential hazards of materials used in welding, such as gases and chemicals. They are crucial for maintaining a safe working environment.

In summary, the documents associated with the Welder Performance Qualification Record are integral to ensuring that welders are adequately qualified and that the welding processes adhere to established standards. Each document serves a specific purpose, contributing to the overall quality and safety of welding operations.